From reviewing your inputs to measurement, 3D modeling, prototyping, and final validation, our 4-step reverse-engineering workflow ensures reliable, 1:1-compatible fit and performance on your equipment.

We offer custom and reverse engineering services for power transmission components, providing 1:1 replacements and upgraded designs for gearboxes, gearmotors and screw jacks.

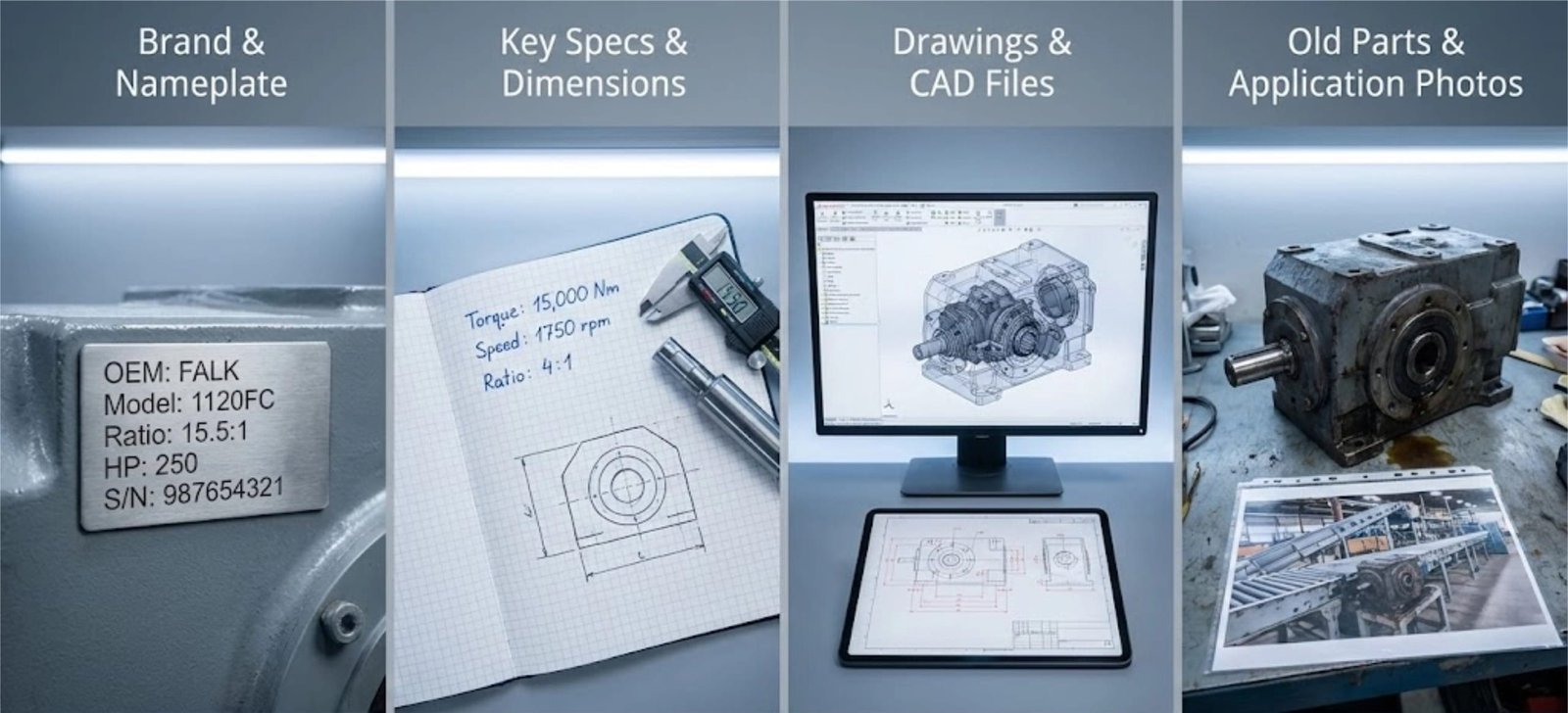

Even if you only have a nameplate photo, a few key dimensions or just an old sample, our engineers can usually recreate – and often optimize – the original part.

New units match the original mounting, torque capacity and ratio, so your machine runs without any redesign.

Where it makes sense, we upgrade materials, heat treatment or sealing to extend service life and reliability.

Shorter lead times and more competitive pricing than OEM spares help you reduce stoppages and total ownership cost.

From reviewing your inputs to measurement, 3D modeling, prototyping, and final validation, our 4-step reverse-engineering workflow ensures reliable, 1:1-compatible fit and performance on your equipment.

Our engineers review your brand/model, photos, data or sample parts and tell you exactly what’s missing so we can move quickly with the minimum information required.

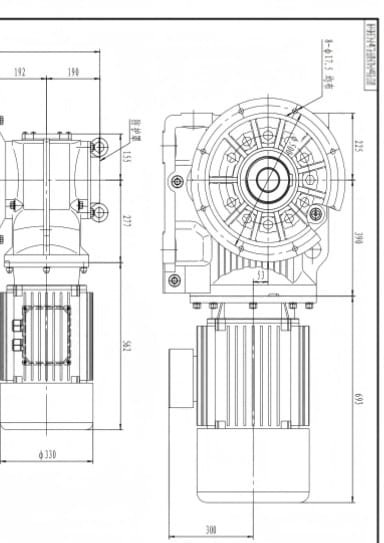

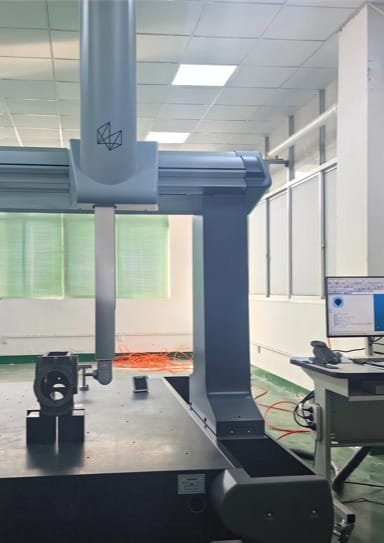

We combine precise measurement with our database of global gearbox parameters to rebuild accurate 2D/3D models that fit your existing machine and working conditions.

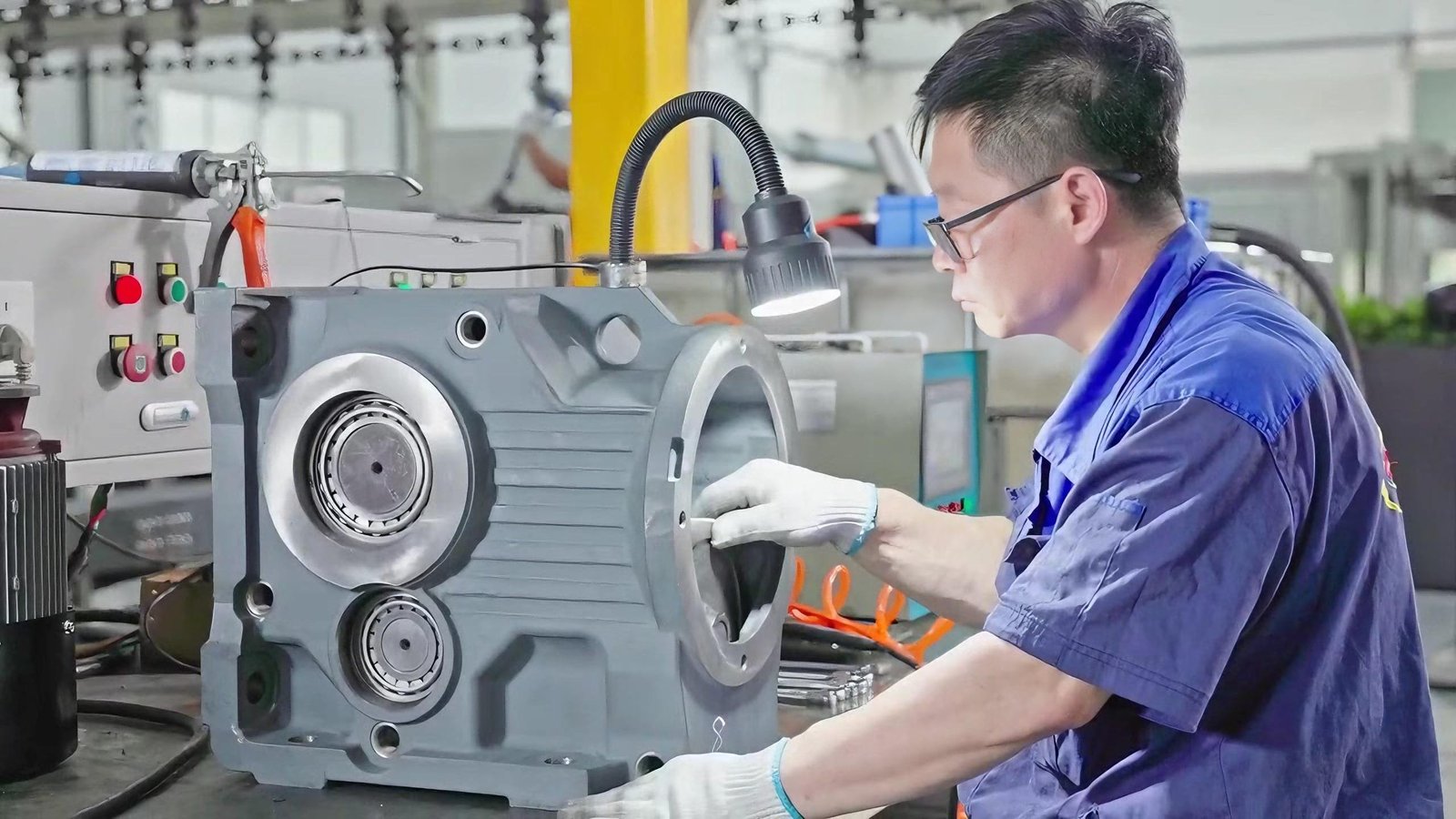

A prototype unit is produced and tested for noise, torque, temperature and leakage, so you receive a part that works in the field, not just on paper.

Once confirmed, we launch batch production with controlled lead time, full QC, material and heat-treatment traceability, ensuring stable quality and reliable delivery.

10,000+

5,000+

8,000+

6,000+

LiuDrive’s reverse engineering is built on proven technical capability—not guesswork. We combine precise measurement, accurate 2D/3D modelling, controlled materials and heat treatment, and documented performance verification to ensure every replacement fits right and runs reliably. With number-backed capability metrics and traceable records, we deliver consistent, production-ready results for gearboxes, screw jacks and irrigation gearboxes.

Reach out to discuss your reverse engineering needs. Our team is ready to help you recreate and optimize your power transmission components.

Share your model numbers, photos or key dimensions and we’ll help you check compatibility and prepare a quotation.

See our workshops, equipment and testing process in person. Leave your details and we’ll arrange a suitable visiting time for you.