Stainless Steel Gearbox Manufacturer

- 100% interchangeable with global brands. Seamless 1:1 replacement.

- OEM/ODM Supported

- Designed for food processing, pharmaceutical, chemical, and washdown environments

- Hygienic & Corrosion-Resistant

Brand Replacement Expertise

Trusted stainless steel gearbox alternatives. Direct 1:1 dimensional replacement for major international stainless steel gearbox brands.

Reduce your total cost of ownership without compromising quality.

Stainless Steel Gearboxes

Looking for a reliable backend factory? LiuDrive offers 304/316/316L stainless steel gearboxes, gearmotors, and screw jacks. 1:1 interchangeable with major brands.

VFN Series Stainless Steel Worm Gearbox

- Up to 650 Nm torque

- 6 housing sizes available

- Hollow bore 14–42 mm

- All stainless steel 316L hardware

VFI Series Stainless Steel Worm Gearbox

- Right-angle transmission structure

- High reduction ratio in compact size

- Self-locking under certain ratios

- Smooth and quiet operation

BVN Stainless Steel Helical Bevel Gearbox

- High-efficiency right-angle drive

- Rigid gear structure for continuous duty

- Stable torque transmission

- Long service life under load

Fortress Stainless Steel Gearbox

- Hypoid bevel gearbox

- All steel internal gearing

- Hypoidal gearing technology

- Lifetime grease lubrication

Stainless Steel Inline Helical Gearmotor

- Shaft configuration: inline

- Size: 37~67

- Ratio: 3.41~199.81

- Input power: 0.18~7.5kW

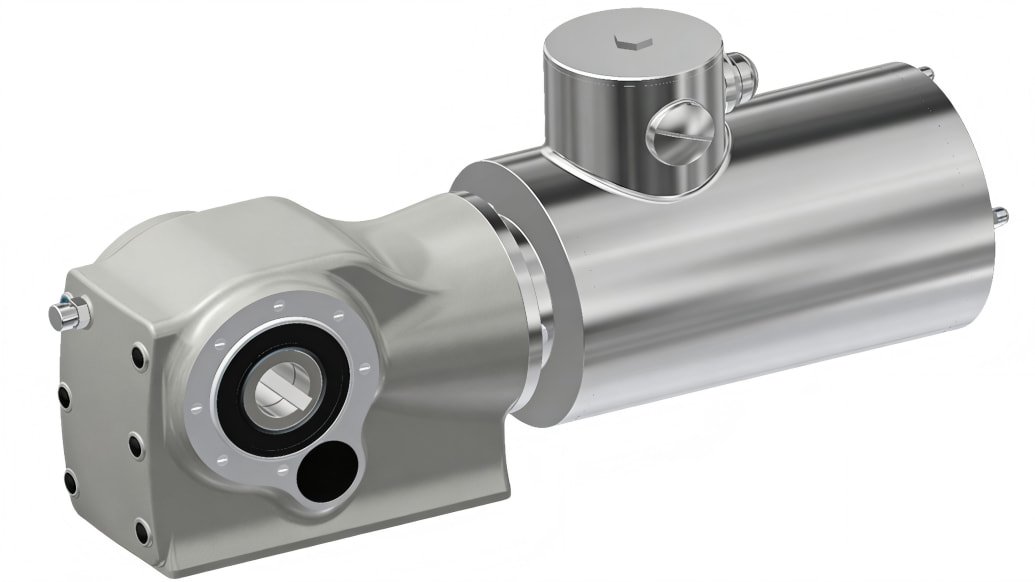

Stainless Steel Helical Bevel Gearmotor

- Shaft configuration: right angle

- Size: 37~67

- Ratio: 3.98~145.14

- Input power: 0.18~5.5kW

SSP Stainless Steel Planetary Gearbox

- Shaft configuration: inline

- Frame size (mm): 42, 60, 90, 115

- Ratio: 3.1-100:1

- Customisation available

Stainless Steel Planetary Gearbox

- Shaft configuration: right angle

- Frame size (mm): 50, 70, 90, 120,155

- Ratio: 3:1-200:1

- Nominal torques up to 650 Nm

Stainless Steel Worm Gearbox

- Ratio:4.83~70

- Efficiency up to 95%

- Power: 0.25~1.5kW

- Torques up to 200N.m

Stainless Steel Screw Jack

- Worm or bevel gear drives

- Translating or rotating designs

- High load & precise control

- Mechanical self-locking option

Stainless Steel Bevel Gearbox

- Compact high-torque design

- Gear ratios from 1:1 to 1:5

- Multiple input/output configurations

- Direct motor or flange mount

Stainless Steel Linear Actuator

- Ball or trapezoidal screws

- Modular mounting options

- Electric alternative to cylinders

- Heavy-duty for harsh environments

No product for you?

Send us your drawing, photo, or nameplate. Our engineers will match a drop-in replacement within 24 hours.

Material & Manufacturing Excellence

We manufacture stainless steel gearboxes to meet hygiene, corrosion resistance, and durability requirements.

- Housing material: 304 / 316 / 316L

- Surface finish: polished / sandblasted

- Stainless steel shafts & fasteners

- Food-grade seals and lubricant available

- IP65 to IP69K protection

- Suitable for washdown environments

Why Choose LiuDrive

LiuDrive supplies stainless steel gearboxes as direct replacements for major brands, with flexible production and long-term supply stability. We manufacture stainless steel gearboxes according to your individual requirements

38+ Years Experience

Focused on power transmission since 1987, with deep understanding of industrial gearboxes and global replacement standards.

1:1 Brand Replacement

Dimensionally interchangeable with major international brands, allowing direct replacement without redesign or machine modification.

Flexible MOQ

From single-unit replacements to volume orders, supporting urgent maintenance needs as well as long-term project sourcing.

Manufacturing Partner

Stable production, flexible capacity, and long-term manufacturing support tailored for distributors and OEM customers.

Engineering & Custom Support

Application-Based Engineering

Selection and customization based on real load, environment, and installation space.

Brand Replacement Expertise

Engineered for direct replacement with matched dimensions and performance.

Customization Capability

Ratios, shafts, mounting, sealing, and surface finish available.

Project & OEM Support

From single replacements to OEM projects with controlled lead times.

Typical Applications

Food & Beverage

Hygienic stainless steel drives for cutting, washing, filling, and packaging lines in food and beverage processing.

Pharmaceutical

Corrosion-resistant drives for pharmaceutical equipment, ensuring easy cleaning and hygienic operation.

Dairy & Meat

Reliable stainless steel gearboxes for cheese, milk, meat, and poultry processing lines in washdown environments.

Chemical

Durable drives for chemical processing systems, resistant to moisture and harsh chemicals.

Packaging & Conveying

Designed for continuous washdown conveyor and packaging systems, keeping production lines hygienic.

Marine

Corrosion-free drives for marine and offshore applications, providing long-lasting performance in harsh environments.

Manufacturing & Quality

We focus on precision machining, controlled assembly, and strict inspection to ensure stainless steel gearboxes meet replacement and OEM requirements.

Quick Buyer Q&A

We have listed some questions from buyers and engineers.

If you need further clarification, send us an inquiry and our team will respond within 24 hours.act us.

Yes. Our stainless steel gearboxes are engineered for 1:1 dimensional interchangeability with major international brands, including SEW, NORD, Grove, Winsmith, and similar manufacturers.

For confirmation, we recommend sending a nameplate photo, drawing, or original model number for verification.

You can send us a drawing, nameplate photo, or complete model number.

Our engineers will match a suitable replacement within 24 hours.

We offer 304, 316, and 316L stainless steel housings and components, depending on corrosion and hygiene requirements.

Yes. We support flexible MOQ, from single-unit replacements to batch production for projects and OEM customers.

Yes. We provide 2D drawings and 3D CAD models to support installation, verification, and approval before production.

Upon request, material certificates and relevant documentation can also be supplied to support food, pharmaceutical, or project compliance requirements.

Knowledge & Technical Guide

Stainless Steel Gearboxes – Buyer Questions & Engineering Answers

Table of Contents

What is a stainless steel gearbox and when should it be used?

A stainless steel gearbox is a power transmission unit with a housing and key components made from corrosion-resistant stainless steel, typically 304, 316, or 316L.

It is primarily used in environments where aluminum or cast iron gearboxes fail prematurely, such as:

Washdown and food processing lines

High-humidity or coastal installations

Chemical, pharmaceutical, and hygienic applications

Compared with aluminum housings, stainless steel gearboxes offer superior corrosion resistance, easier cleaning, and longer service life, especially under frequent water or chemical exposure.

Why choose a stainless steel gearbox instead of aluminum?

While aluminum gearboxes are lighter and lower cost, they are vulnerable to corrosion, pitting, and coating damage in aggressive environments.

Stainless steel gearboxes provide:

Excellent corrosion resistance without surface coatings

Improved hygiene and cleanability

More stable long-term performance in wet or corrosive conditions

For washdown or hygiene-critical applications, stainless steel gearboxes significantly reduce maintenance frequency and unexpected downtime.

What types of stainless steel gearboxes are commonly used?

The most common stainless steel gearbox types include:

Right angle gearboxes – compact design for 90° power transmission

Worm gearboxes – self-locking and suitable for low-speed, high-torque applications

Bevel gearboxes – higher efficiency than worm drives for right-angle layouts

Inline and planetary gearboxes – used where precision and compactness are required

The correct type depends on torque, speed, installation space, and environmental conditions.

What stainless steel materials are available?

We commonly supply stainless steel gearboxes in:

304 stainless steel – general corrosion resistance

316 stainless steel – improved resistance to chemicals and chlorides

316L stainless steel – enhanced hygiene and weldability

Material selection depends on corrosion level, cleaning frequency, and industry standards.

Request Quote Now !

Our proficient engineers are ready to partner with you in developing the ultimate personalized shipping experience.